Manual Filter Press vs Automatic Filter Press is one of the most common comparisons when industries plan to invest in a filtration system. Both machines are designed for solid-liquid separation, but they differ significantly in operation, cost, efficiency, and suitability for different production scales.

This in-depth guide will help you understand the differences, advantages, limitations, and use cases so you can choose the right solution for your application.

What Is a Manual Filter Press?

A manual filter press is a basic filtration machine where most operations are performed by operators. Plate shifting, cake removal, and cycle handling require human effort. The design is simple, robust, and cost-effective, making it suitable for small to medium-scale industries.

In the Manual Filter Press vs Automatic Filter Press comparison, the manual option is often chosen for low-volume production and budget-sensitive projects.

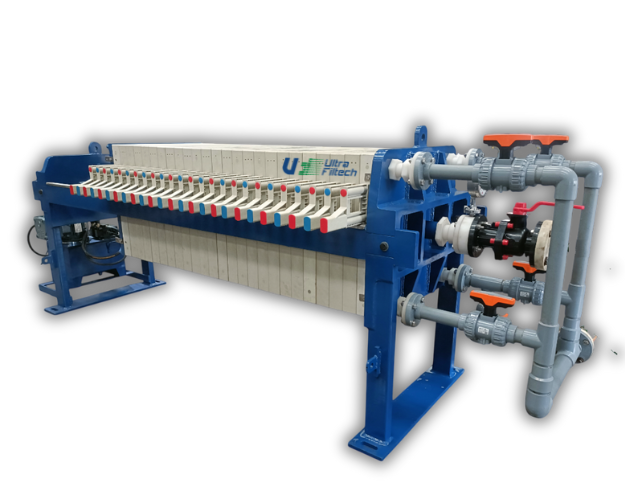

What Is an Automatic Filter Press?

An automatic filter press is an advanced filtration system that automates major steps such as plate closing, filtration control, cake discharge, and cloth washing. It uses hydraulic and electronic systems to reduce manual intervention and increase productivity.

When evaluating Manual Filter Press vs Automatic Filter Press, the automatic version is preferred for large-scale, continuous, and high-efficiency operations.

Key Differences: Manual Filter Press vs Automatic Filter Press

1. Level of Automation

The biggest difference in Manual Filter Press vs Automatic Filter Press is automation. Manual systems depend heavily on operators, while automatic systems perform most tasks automatically.

2. Production Capacity

Manual machines are suitable for low to medium production volumes. Automatic machines are designed for high-capacity and continuous operations.

3. Operating Cost

Manual systems have lower initial cost but higher labor dependency. Automatic systems require higher investment but reduce long-term labor and operating costs.

4. Filtration Cycle Time

In the Manual Filter Press vs Automatic Filter Press comparison, automatic machines complete cycles faster due to optimized and controlled processes.

5. Labor Requirement

Manual machines need more manpower for operation and cleaning. Automatic machines significantly reduce human involvement.

Performance and Efficiency Comparison

When comparing Manual Filter Press vs Automatic Filter Press, efficiency becomes a key factor. Automatic systems offer consistent cycle times, uniform cake discharge, and better process control. Manual systems, while reliable, depend on operator skill and experience, which can cause variation in performance.

Maintenance and Reliability

Manual machines are simpler in construction, making maintenance easier and less expensive. Automatic machines have more components such as sensors, hydraulics, and control systems, which require skilled maintenance. However, in the long run, automatic systems often deliver better uptime in high-volume operations.

In the Manual Filter Press vs Automatic Filter Press decision, maintenance capability should always be considered.

Cost Comparison

Manual systems: Lower purchase cost, higher labor cost over time

Automatic systems: Higher purchase cost, lower long-term operating cost

This cost structure is a major deciding factor in the Manual Filter Press vs Automatic Filter Press evaluation.

Which Industries Should Choose Which?

Manual Filter Press Is Ideal For:

Small and medium industries

Low production volumes

Budget-limited projects

Simple and batch-based operations

Automatic Filter Press Is Ideal For:

Large-scale industries

Continuous or high-volume production

Plants aiming for high efficiency and consistency

Operations with high labor cost

How to Choose Between Manual Filter Press vs Automatic Filter Press

To decide between Manual Filter Press vs Automatic Filter Press, consider:

Your daily filtration volume

Available manpower

Budget and return on investment

Required level of process control

Space and infrastructure

The right choice depends on balancing investment with long-term operational goals.

Common Mistakes When Choosing a Filter Press

Some industries choose only based on price and ignore future expansion, labor cost, and efficiency needs. In the Manual Filter Press vs Automatic Filter Press comparison, it is important to think long-term rather than only short-term savings.

Conclusion

Manual Filter Press vs Automatic Filter Press is not about which machine is better overall, but which one is better for your specific application. Manual systems offer simplicity and low cost, while automatic systems deliver high productivity, consistency, and lower long-term operating expenses.

By carefully evaluating your production needs, budget, and growth plans, you can choose the filtration system that provides the best performance and value for your business.