When it comes to industrial filtration, the automatic filter press stands out as one of the most efficient and cost-effective machines. From mining and chemical industries to wastewater treatment plants, filter presses are used worldwide to separate solids from liquids. But what makes an automatic filter press different from traditional manual ones, and how does it actually work? Let’s explore this in detail.

What is an Automatic Filter Press?

An automatic filter press is a mechanical device designed to separate solids from liquids in a slurry mixture through pressure filtration. Unlike manual or semi-automatic filter presses, an automatic filter press minimizes human intervention by using automation systems for:

- Plate shifting

- Cake discharge

- Cloth washing

- Hydraulic operations

This makes it ideal for industries where large volumes of slurry need to be processed continuously with minimal downtime.

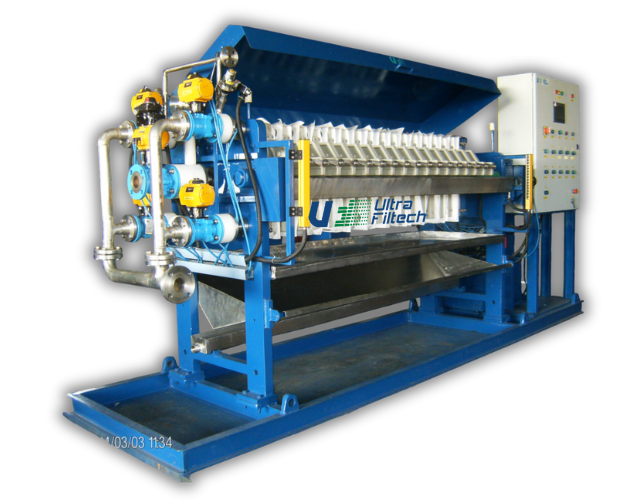

Key Components of an Automatic Filter Press

Before diving into the working process, it’s important to understand the main components:

- Filter Plates – These plates create chambers where filtration takes place. They are usually made of polypropylene for durability and chemical resistance.

- Filter Cloth – A permeable cloth fitted on the plates that captures solid particles while allowing liquid (filtrate) to pass through.

- Hydraulic System – Controls the movement and pressure applied to filter plates.

- Plate Shifting Mechanism – Automatically moves plates for discharging cakes after filtration.

- Drip Tray & Piping System – Collects and directs the filtrate (clean liquid) away from the press.

- Cake Discharge System – Removes solid cakes automatically, reducing manual labor.

- PLC Control Panel – Automates and monitors the entire operation.

Step-by-Step Working of an Automatic Filter Press

Here’s how the process works:

1. Slurry Feeding

The slurry (mixture of solids and liquids) is pumped into the filter press chambers under pressure. The feed pump forces the slurry through the center feed port into the chambers formed between filter plates.

2. Filtration Begins

- The filter cloth traps solid particles on its surface.

- Liquid (filtrate) passes through the cloth and exits via filtrate discharge ports.

- Over time, a solid layer—called the filter cake—begins to build on the cloth surface.

3. Cake Formation

As filtration continues:

- The cake layer becomes thicker.

- The filtrate becomes clearer because the cake itself starts acting as a filtering medium.

- Pressure inside the chamber gradually rises until it reaches the set limit.

4. Automatic Cake Drying (Optional)

Some automatic filter presses use compressed air or water to further reduce moisture in the cake before discharge. This step improves cake dryness and makes handling easier.

5. Plate Opening and Cake Discharge

Once the filtration cycle is complete:

- The hydraulic system releases pressure.

- The plate shifting mechanism automatically separates the plates one by one.

- Solid cakes fall out of the chambers into a collection hopper or conveyor.

This eliminates the need for manual scraping, saving time and labor.

6. Cloth Washing (Automatic)

Filter cloths can get clogged after multiple cycles. Automatic filter presses are equipped with cloth washing systems (high-pressure water jets) that clean the cloths and restore permeability, ensuring consistent filtration efficiency.

7. Cycle Repeats

The plates close again, and the filter press is ready for the next batch.

Advantages of Automatic Filter Press

- Fully Automated – Minimal human involvement, ideal for continuous operations.

- High Efficiency – Produces drier cakes and clearer filtrate.

- Labor Saving – Automatic plate shifting and cake discharge reduce manual work.

- Consistency – Uniform pressure and operation lead to reliable performance.

- Scalability – Available in different sizes to handle small, medium, or large volumes.

Applications of Automatic Filter Press

Automatic filter presses are used in industries such as:

- Mining & Metallurgy – For dewatering mineral concentrates.

- Chemical Manufacturing – To separate valuable chemicals from impurities.

- Food & Beverage – For processes like sugar refining, fruit juice clarification, and edible oil filtration.

- Pharmaceuticals – To obtain pure liquid extracts.

- Wastewater Treatment – For sludge dewatering in municipal and industrial plants.

Final Thoughts

An automatic filter press simplifies the solid-liquid separation process by combining robust mechanical design with smart automation. By reducing labor, increasing efficiency, and producing high-quality output, it has become an indispensable tool across multiple industries.

If your operation involves large-scale slurry treatment, investing in an automatic filter press can significantly improve productivity, reduce costs, and ensure reliable performance.