A manual filter press is one of the most reliable and cost-effective solid-liquid separation machines used across industries like chemicals, pharmaceuticals, food processing, textiles, mining, and wastewater treatment.

Its simple design, low maintenance, and efficient filtration capability make it a preferred choice for small and medium-scale industries.

In this guide, we explain how a manual filter press works, its components, benefits, applications, and why industries continue to trust this traditional yet powerful filtration technology.

What Is a Manual Filter Press?

A manual filter press is a mechanical device where all operations—plate shifting, pump control, and filter cake discharge—are operated manually without automation.

Because it has fewer moving parts and no electrical dependency, it is known for:

Durability

Low initial cost

Low maintenance

High filtration efficiency

Industries use manual filter presses when production volume is moderate and filtration needs to be controlled manually.

Working Principle of a Manual Filter Press

The working principle is based on pressure filtration — separating solids from liquids by applying pressure through plates, frames, and filter cloths.

Below is the full working process:

1. Slurry Is Pumped Into the Filter Chambers

The slurry (mixture of solid and liquid) is pumped into the press.

Each pair of plates creates a chamber where filtration happens.

Liquid flows inside through the feed pump

Solids begin to accumulate on the filter cloth

Pressure increases as the chamber fills

Higher pressure results in better filtration.

2. Filter Cloth Retains Solid Particles

Each filter plate is covered with a filter cloth.

The cloth traps solid particles

Clear filtrate passes through the cloth

The pore size affects filtration quality

Cloth selection is critical in industries requiring high purity.

3. Filtrate Flows Out Through Channels

After passing through the cloth:

Filtrate travels through drainage channels in the plates

It exits the press from the outlet ports

Clean liquid is collected for reuse or disposal

The clarity of filtrate depends on cloth mesh and pressure.

4. Filter Cake Formation

As filtration continues:

Solids build up on the cloth

A dense “filter cake” is formed

Filtration rate slows as cake thickness increases

A fully formed cake indicates the end of filtration.

5. Manual Opening of Plates

After the cycle:

The operator loosens the manual screw or hydraulic jack

Plates are separated by hand

The filter cake becomes visible

Manual movement lowers machine cost and maintenance.

6. Cake Discharge

With plates open:

Filter cake is manually removed

Cloth is brushed or washed

Plates are re-closed for the next cycle

This simple mechanism makes operation easy and economical.

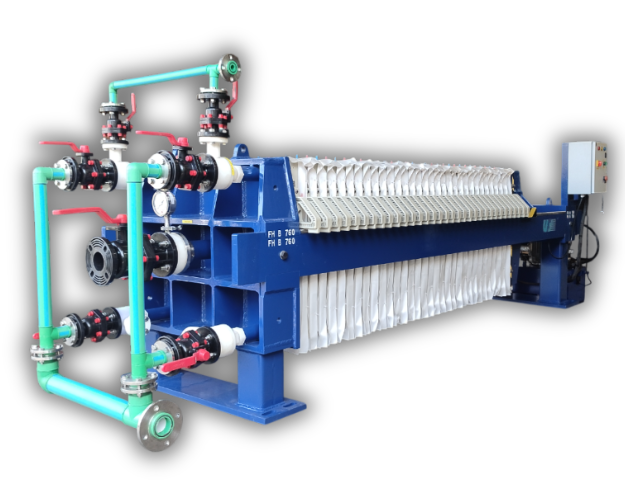

Key Components of a Manual Filter Press

A manual filter press includes:

Filter Plates

Filter Cloth

Structural Frame

Manual Closing Screw or Jack

Feed Pump

Drip Trays

Slurry Inlet System

Filtrate Outlet Channels

Each part affects filtration efficiency and cycle time.

Benefits of a Manual Filter Press

Manual filter presses offer strong advantages:

● Low investment cost

● Easy to operate—no automation needed

● Highly durable with minimal breakdown

● Low maintenance and affordable spare parts

● Good filtration efficiency with dry cake output

Applications of Manual Filter Press

Manual filter presses are widely used in:

Chemical processing

Food and beverage industry

Dyes and pigment manufacturing

Wastewater treatment plants

Mining and minerals

Pharmaceuticals

Oil and edible industry

Ceramic and clay processing

Any industry requiring solid-liquid separation can use this machine.

Manual Filter Press vs Automatic Filter Press

| Feature | Manual Filter Press | Automatic Filter Press |

|---|---|---|

| Operation | Manual | Fully automated |

| Cost | Low | High |

| Maintenance | Low | Moderate |

| Labor Requirement | High | Low |

| Efficiency | Moderate | High |

| Plate Shifting | Manual | Automatic |

Choose a manual press when your budget is limited and operation requires hands-on control.

Why Choose UltraFiltech for Manual Filter Presses?

UltraFiltech is a trusted filter press manufacturer in India, providing:

High-quality manual filter press machines

Heavy-duty body and corrosion-resistant materials

Durable plates and long-life filter cloth

Custom sizes from 300 mm to 1500 mm

Excellent after-sales support and spare parts

Our machines are known for reliability, performance, and long service life.

Conclusion

A manual filter press works on a straightforward yet powerful principle of pressure filtration, making it ideal for industries that need reliable and cost-efficient solid-liquid separation.

With simple operation, low maintenance, and durable construction, manual filter presses remain one of the most widely used filtration systems in India.

If you’re searching for a manual filter press manufacturer in India, UltraFiltech offers customized solutions for every industry.