In industries that deal with solid-liquid separation, a filter press machine is one of the most trusted and widely used pieces of equipment. While technology has advanced to include semi-automatic and fully automatic systems, the manual filter press machine remains a popular choice for small-scale industries and low-volume operations.

If you’re wondering what a manual filter press is, how it works, and whether it’s suitable for your business, this guide covers everything you need to know.

What is a Manual Filter Press Machine?

A manual filter press machine is a type of pressure filtration device that relies completely on human effort for its operation. It is the simplest and most economical version of a filter press, ideal for small-scale operations where cost efficiency is important and production volumes are relatively low.

Unlike semi-automatic or automatic filter presses, it does not have hydraulic systems or automated plate shifting mechanisms. Instead, operators manually:

Close and open the filter plates

Tighten the press using a screw or hand wheel

Discharge the filter cakes

Clean the filter cloths between cycles

This makes it low-cost and easy to operate, but more labor-intensive.

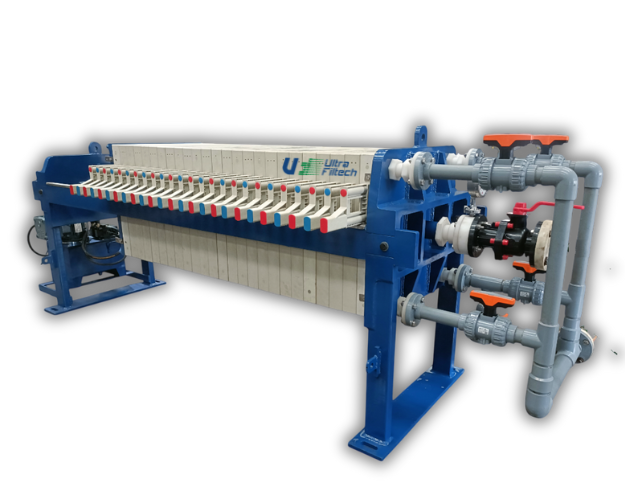

Key Components of a Manual Filter Press

Although simpler, the manual filter press consists of essential components similar to other types:

Filter Plates – Create chambers for slurry feeding and filtration.

Filter Cloth – Traps solid particles while allowing liquid to pass through.

Frame – Provides structural support and alignment for plates.

Hand Screw / Wheel Mechanism – Used by the operator to tighten and seal the plates manually.

Slurry Inlet – Point where slurry is pumped into the machine.

Filtrate Outlets – Channels that remove filtered liquid.

Drip Tray (Optional) – Collects any leakage.

How Does a Manual Filter Press Work?

The working of a manual filter press can be explained step by step:

1. Plate Closing

The operator manually pushes the filter plates together and tightens them using a hand screw or wheel. This ensures the chambers are sealed tightly before filtration begins.

2. Slurry Feeding

Slurry (a mixture of solids and liquid) is pumped into the chambers formed between the plates.

3. Filtration Process

The filter cloths hold back solid particles.

The clean liquid (filtrate) passes through the cloth and exits via discharge outlets.

Gradually, a solid layer known as the filter cake builds on the cloth surface.

4. Cake Formation

As pressure builds, the cake becomes thicker and drier, while filtrate clarity improves.

5. Cake Discharge

Once filtration is complete, the operator manually releases the pressure, separates the plates, and removes the solid cakes by scraping them off.

6. Cloth Cleaning

Filter cloths are cleaned manually before starting the next cycle.

Advantages of a Manual Filter Press

Low Cost – The most affordable type of filter press.

Simple Design – Easy to operate and maintain.

Durable – With fewer mechanical and electronic parts, breakdowns are minimal.

Best for Small-Scale Use – Perfect for operations with low slurry volumes.

Portable – Smaller in size, can be moved and installed easily.

Limitations of a Manual Filter Press

Labor-Intensive – Requires continuous manual operation.

Lower Productivity – Slower cycle time compared to semi-automatic or automatic presses.

Not Ideal for Large Scale – Unsuitable for industries with high slurry volumes.

Manual Cake Discharge – Can be time-consuming and physically demanding.

Applications of Manual Filter Press

Manual filter presses are commonly used in:

Small Mining Operations – For separating ore slurries.

Food & Beverages – Juice clarification, small-scale edible oil processing.

Pharmaceuticals – Low-volume separation of extracts and ingredients.

Chemical Processing – For small-batch chemical separations.

Wastewater Treatment (Small Plants) – Sludge dewatering in labs or pilot plants.

Manual vs Semi-Automatic vs Automatic Filter Press

| Feature | Manual | Semi-Automatic | Automatic |

|---|---|---|---|

| Operation | Fully manual | Partial automation | Fully automated |

| Plate Closing | Hand screw/wheel | Hydraulic | Hydraulic |

| Cake Discharge | Manual | Manual | Automatic |

| Labor Requirement | High | Medium | Very low |

| Cost | Lowest | Moderate | Highest |

| Best For | Small-scale operations | Medium-scale industries | Large-scale industries |

Final Thoughts

A manual filter press machine is the simplest and most economical choice for businesses that need basic solid-liquid separation without investing in expensive automation. While it may not be suitable for high-volume production, it remains an excellent option for small-scale industries, pilot plants, and cost-conscious businesses.

If you’re just starting with filtration or handling small batches, a manual filter press offers reliability, simplicity, and affordability.